Brother nailed it with this product!

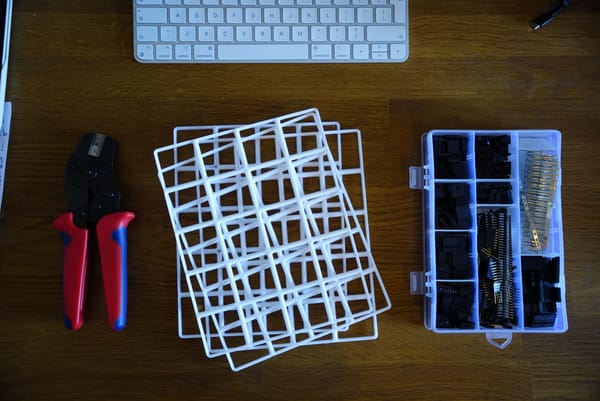

I use a label maker to organise the space around me at the office.

We often work with digital assets, but physical assets management is just as essential to enable human ingenuity to thrive. Since my business crossed into tangible product design, this is a product I interact with often.

Let me tell you what makes this particular design great - perhaps things we can all consider for our next designs.

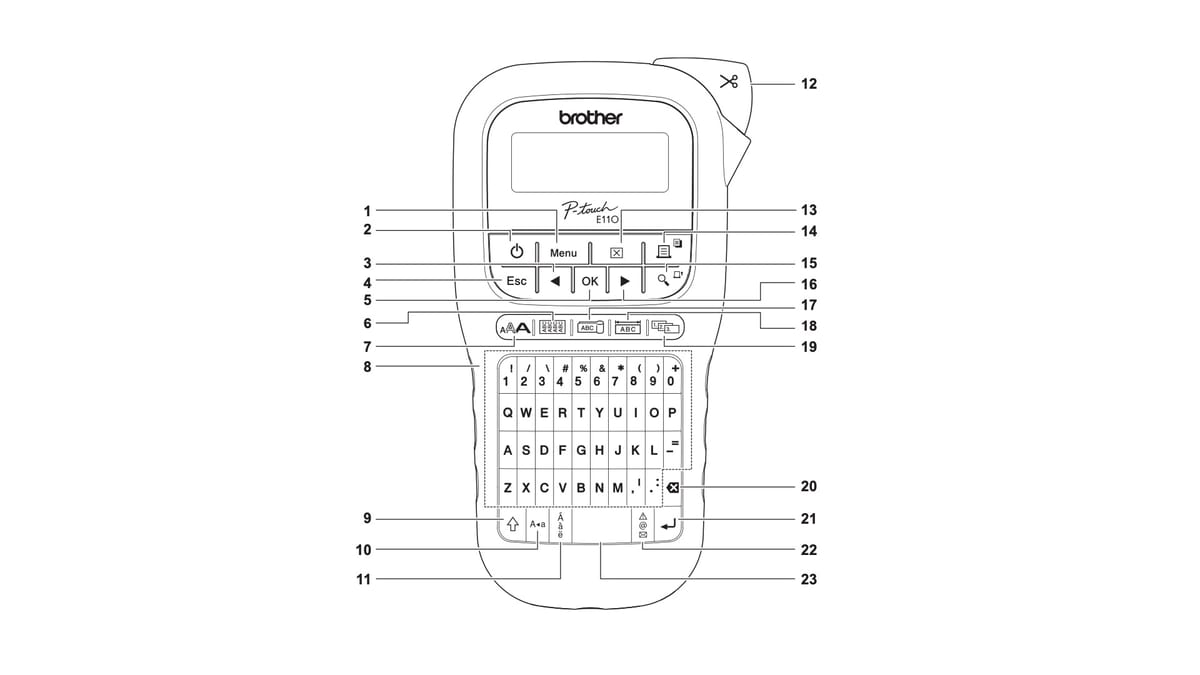

Instructions written for the user

- Visual user guide to get your started quickly

- Systematic user manual easy to follow - great structure, succinct language, simple annotations exactly where they are required

- Clear information about troubleshooting, online resources and compatible consumables

- It even includes information about user repairs!

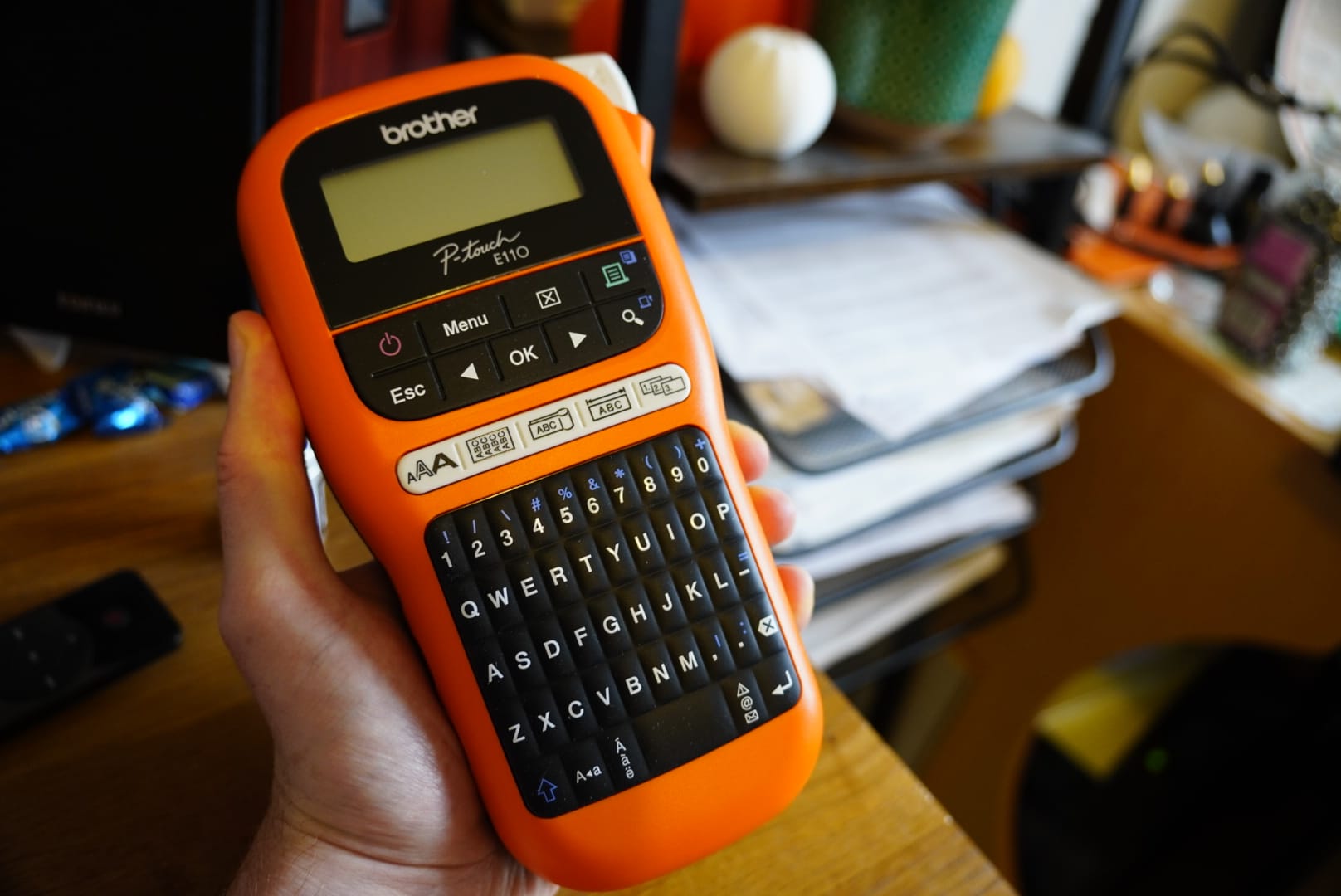

Made for human hands

- It fits the palm like a glove!

- Materials + colours + textures choice for durability and easy use

- Buttons are satisfying to use, the whole unit feels solid!

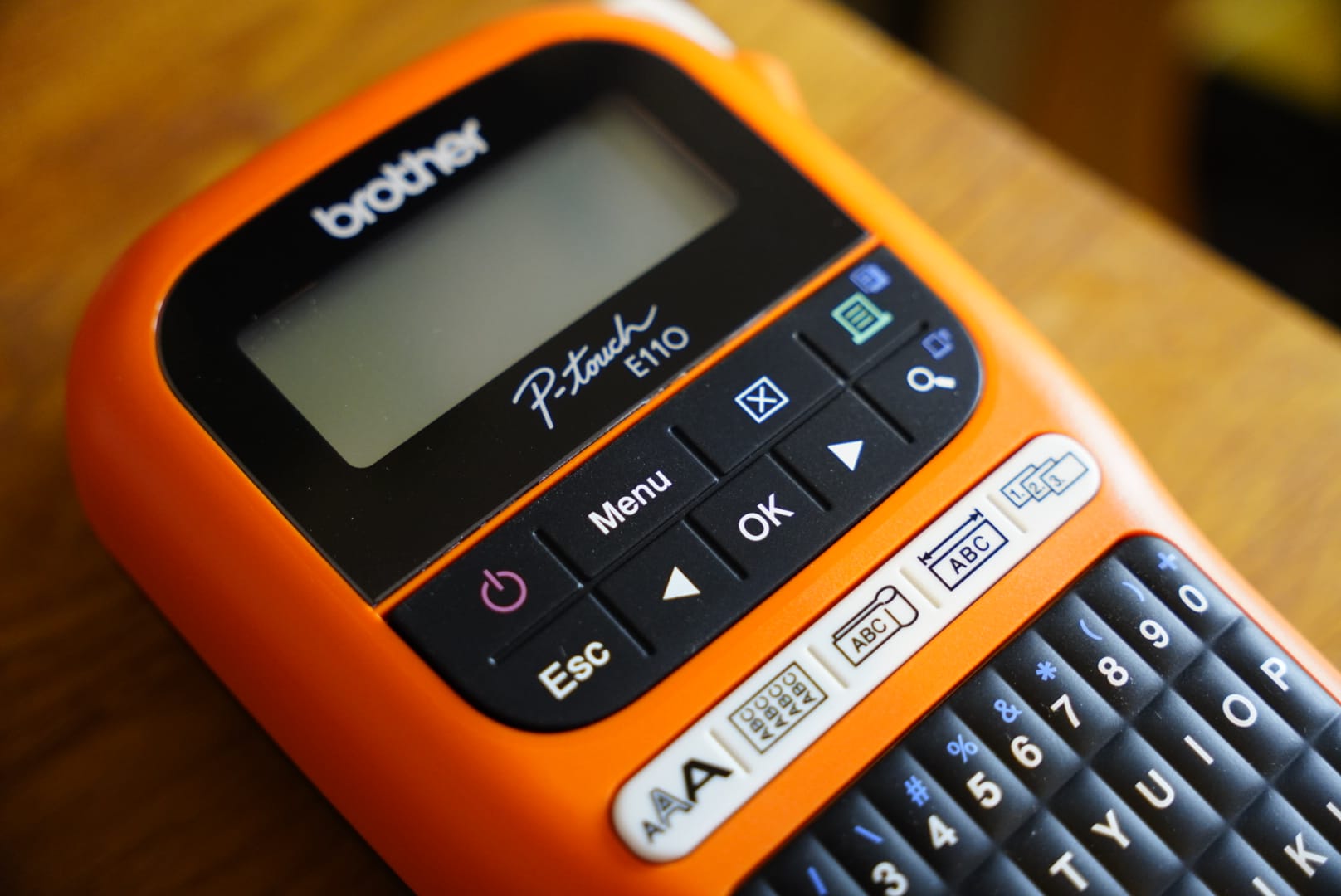

Important functions, immediately accessible

- Fewer features mean less friction. Instead of hiding behind companion apps or menus, the key functions are clearly laid out as physical buttons, labeled with text or intuitive pictograms.

- Fewer choices = more freedom. Freedom from unnecessary decisions. The designers did the heavy lifting and came up with the perfect small set of presets/ styles, so that I don't have to fiddle with 100x fonts/ sizes every time I want to print a label.

- Layout is intuitive. Buttons are grouped in logical sets (top: setup, middle: preset, bottom: keyboard)

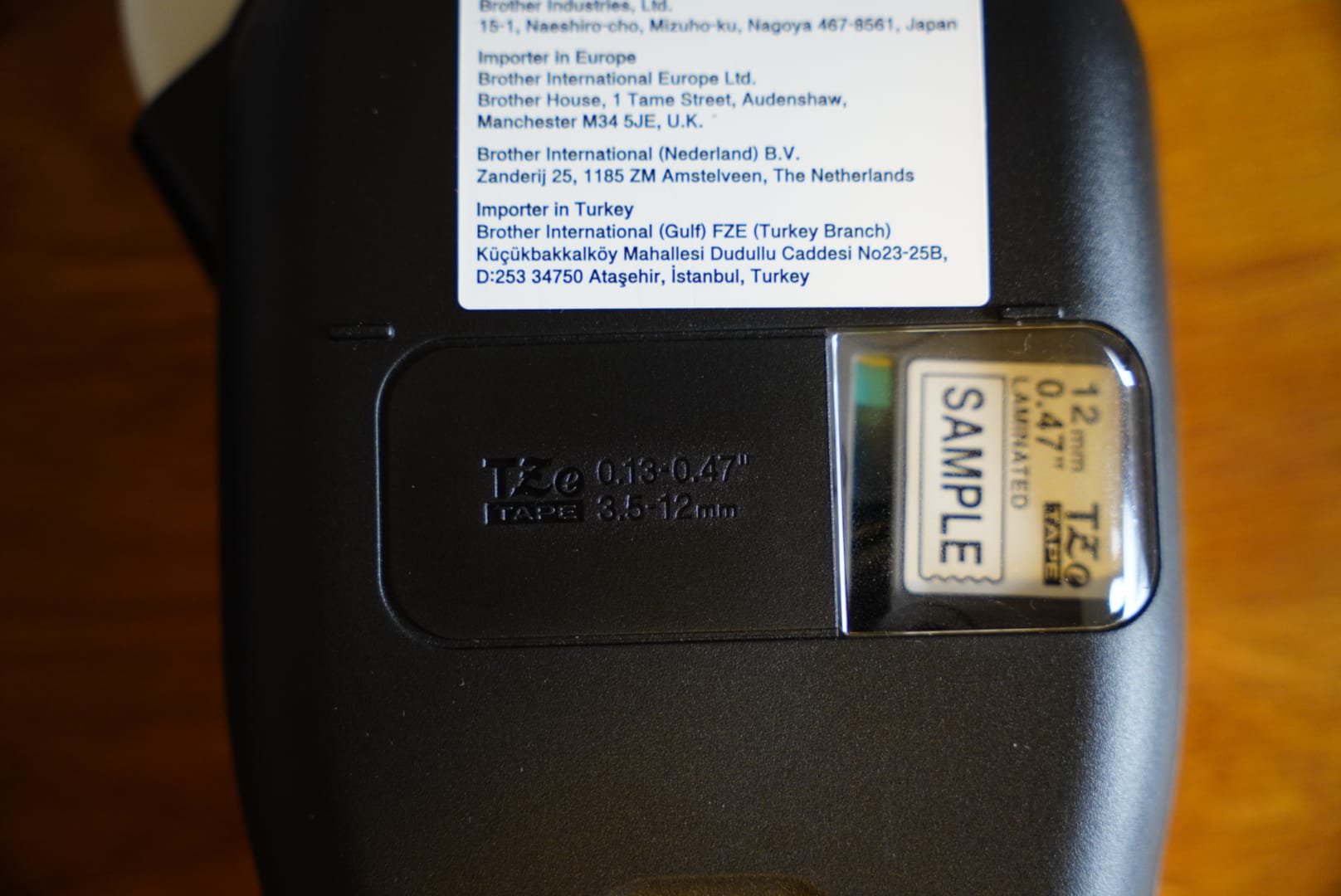

Consumable level and type is one glance away

- The back of the product lists the exact specifications of compatible consumables—part of the injection mould, so it’s permanently there.

- There’s a window to see the cartridge currently loaded and its fill level - great design (no need for sensors, complicated tags, electronics, cloud)

Powering gives your options, not locks you in

- Replaceable batteries is a huge plus as the battery is that component that usually fails first

- AAA batteries might seem like a drawback, but they’re not—you can swap them out instantly and keep working. You are not dependent on specially manufactured chips/ batteries to operate the device

- What happens when you don't have batteries? You can plug this in via a standard DC barrel port, and run off the mains

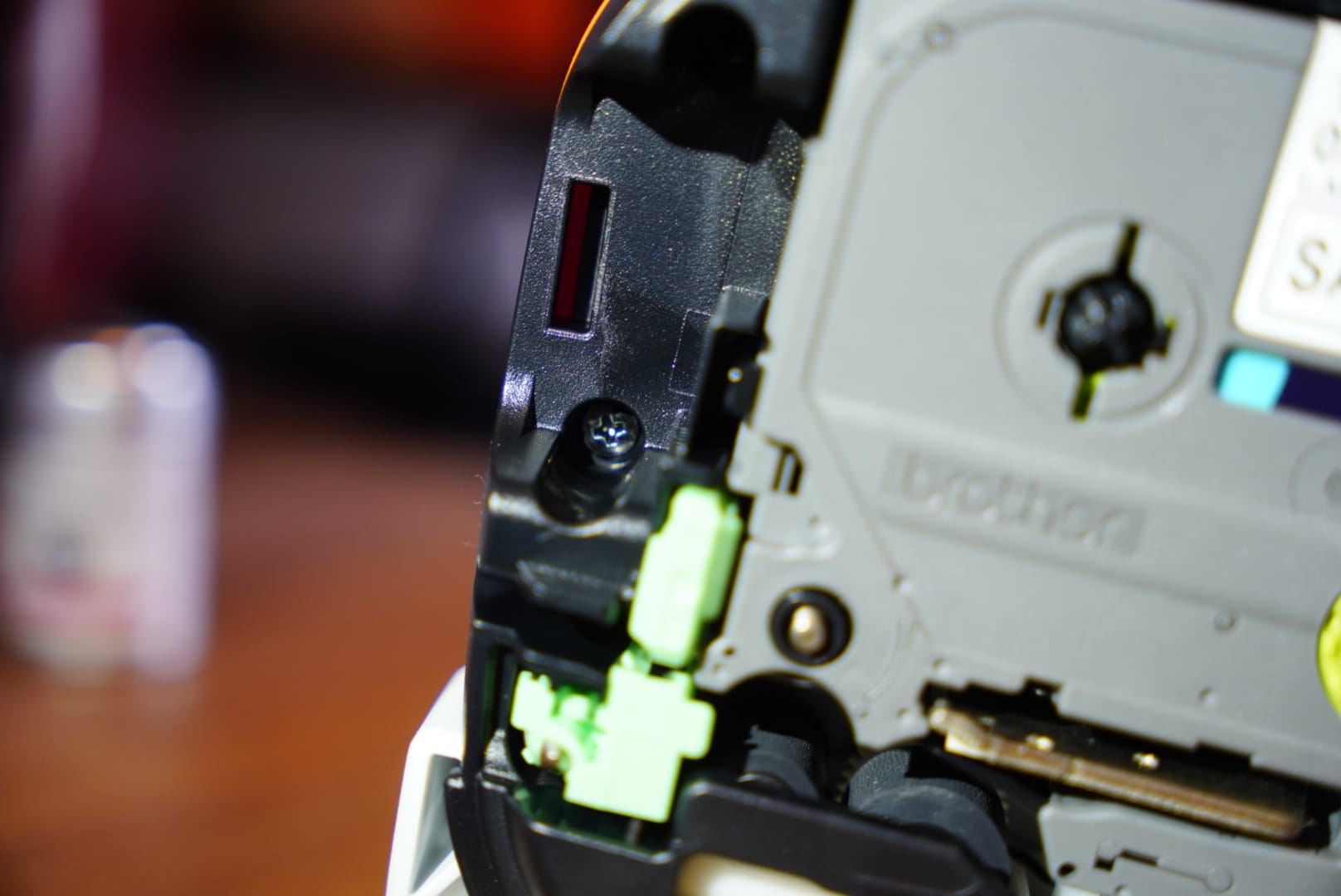

Easy to take apart and repairable

- The back cover comes off easily to reveal a rare sight: standard Phillips screws!

- Furthermore, the components that are most likely to wear out first (the cutter blades) are clearly differentiated and you can purchase cheap replacements for

- In fact you can purchase cheap replacements for most components - remember, the overall product only costs $15-30 in its entirety. This is commitment towards good, sustainable design!

Is it perfect?

No. There are some mild annoyances. I will mention 3x that would dramatically improve my user experience.

- Blade mechanism is too recessed from the edge. This means that there is a forced wide border around the labels which makes you use more tape than ideal. Over time, this compounds to a lot more waste than I'd like!

- The design is clearly for right-handed people. About 10% of users may find it slightly awkward to operate the guillotine lever, which is placed on the far right of the device. A more ambidextrous design would be preferable.

- Shift + Backspace should clear all text, but it doesn't (even thought Shift triggers special functions of other keys). Absent of this, you can either hold Backspace to clear the text one letter at a time OR navigate the Clear menu (at the very top of the buttons) - this takes you away from the keyboard section, and feels unnecessarily cumbersome for an operation that is required for every single new label produced.

- Relies on having scissors around, and this adds friction. Because it can't do cuts or half-cuts, for most functions I actually find myself using (e.g. anything with smaller borders, chain printing, etc.) the embedded guillotine is not sufficient. I have to use scissors to trim margins, edges, or cut between labels - ideally, this should be done on device (at least some operations could be prompted with a pause and a prompt to cut via the embedded blade, but they are not).

It'd be interesting to see how other products in their range are dealing with these (e.g. the E560BT, which addresses at least some of the shortcomings above).

Would I recommend this product?

Absolutely! This is a fantastic product that will likely serve me and my business for the next decade or more.